With more than 600 food products derived from maize, Mexico is the fifth largest maize consumer globally, and the only country where more than 70% of the maize produced is used for direct human consumption. Farmers in Mexico grow maize mainly for home consumption, the nixtamalized flour industry, and the tortilla dough industry. The product’s end-use quality is greatly determined by the quality of the maize grain. Therefore, for the Mexican market, as well as for processors and consumers, grain quality is crucial.

Since the beginning of MasAgro, special emphasis has been placed on monitoring the quality of improved maize varieties to ensure that they meet the needs of Mexico’s traditional and industrial nixtamalization processes. Continuous exchanges of scientists with millers and tortilla dough entrepreneurs have been crucial for developing robust and cost-efficient analytical methods that different actors in the maize value chain can use to monitor grain quality. Offering analytical tools to the tortilla dough industry so it can move from empirical to analytical knowledge will help to optimize and professionalize its business.

Nixtamalization: the process of cooking and steeping dried maize grain in water and lime (calcium hydroxide) in order to unlock important nutritional benefits.

Grain hardness, color, and size are three basic quality parameters that the industry demands from producers. However, they are normally found only in grain produced in specific regions of Mexico (Sinaloa, Bajío, and sometimes Guerrero, Michoacán, and Morelos). Although several factors, including environmental effects, play a role in determining grain quality, the genetic factor is crucial. Seed companies working with MasAgro are becoming aware of the importance of developing and commercializing improved seed that meets farmers’ demands; farmers, in turn, have to meet industry requirements.

Grain hardness, color, and size are three basic quality parameters that the industry demands from producers. However, they are normally found only in grain produced in specific regions of Mexico (Sinaloa, Bajío, and sometimes Guerrero, Michoacán, and Morelos). Although several factors, including environmental effects, play a role in determining grain quality, the genetic factor is crucial. Seed companies working with MasAgro are becoming aware of the importance of developing and commercializing improved seed that meets farmers’ demands; farmers, in turn, have to meet industry requirements.

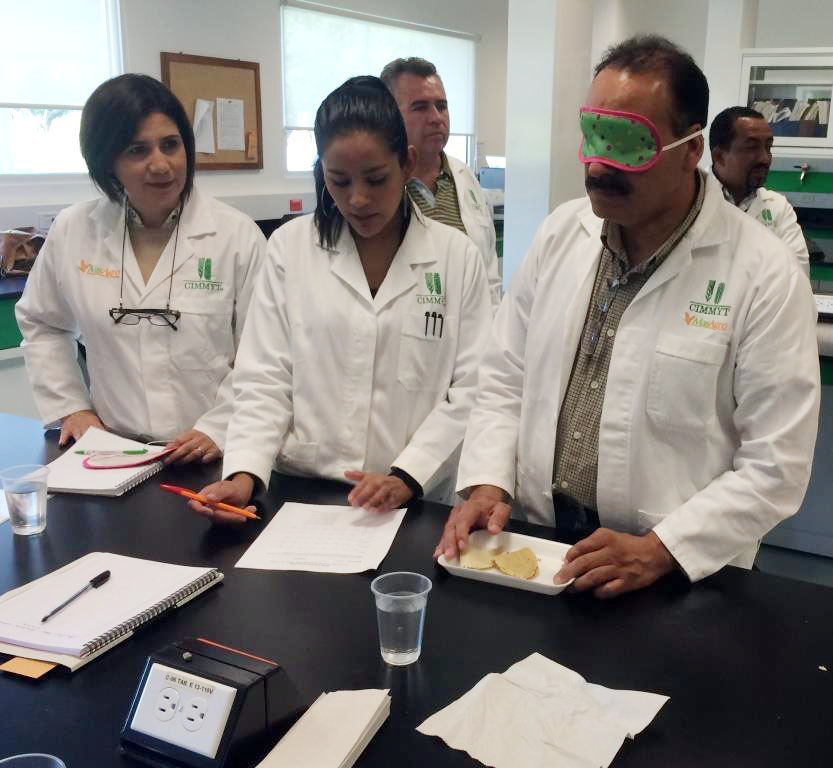

Last month MasAgro hosted more than 25 participants from seed companies in a maize quality training course led by INIFAP and CIMMYT. In CIMMYT’s maize quality laboratory, participants learned the effect grain quality has on the production process and the final product. To monitor quality, they used several methodologies, ranging from specialized equipment, such as a test weight scale and colorimetric devices, to common sugar solutions having a specific density, and smart phones with applications that measure kernel hardness and color.

Last month MasAgro hosted more than 25 participants from seed companies in a maize quality training course led by INIFAP and CIMMYT. In CIMMYT’s maize quality laboratory, participants learned the effect grain quality has on the production process and the final product. To monitor quality, they used several methodologies, ranging from specialized equipment, such as a test weight scale and colorimetric devices, to common sugar solutions having a specific density, and smart phones with applications that measure kernel hardness and color.

Through experimentation and sensory studies of tortillas produced from kernels of contrasting quality, participants learned how raw materials affect consumer acceptance of a food product. During a very enthusiastic discussion about Mexico’s maize value chain, participants expressed their desire to have more frequent exchanges with different actors in the value chain. They also learned the value of market organization, storage infrastructure, and scientific research that addresses sector needs.

Capacity development

Capacity development