In response to increasing labor scarcity and costs, growth in mechanized wheat and rice harvesting has fueled farm prosperity and entrepreneurial opportunity in the poorest parts of Nepal, researchers from the International Maize and Wheat Improvement Center (CIMMYT) have recorded.

Farmers are turning to two-wheeled tractor-mounted reaper-harvesters to make up for the lack of farm labor, caused by a significant number of rural Nepalese — especially men and youth — migrating out in search of employment opportunities.

For Nandalal Oli, a 35-year-old farmer from Bardiya in far-west Nepal, investing in a mechanized reaper not only allowed him to avoid expensive labor costs that have resulted from out-migration from his village, but it also provided a source of income offering wheat and rice harvesting services to his neighbors.

“The reaper easily attaches on my two-wheel tractor and means I can mechanically cut and lay the wheat and rice harvests,” said Oli, the father of two. “Hiring help to harvest by hand is expensive and can take days but with the reaper attachment it’s done in hours, saving time and money.”

Oli was first introduced to the small reaper attachment three years ago at a farmer exhibition hosted by Cereal Systems Initiative for South Asia (CSISA), funded through USAID. He saw the reaper as an opportunity to add harvesting to his mechanization business, where he was already using his two-wheel tractor for tilling, planting and transportation services.

Prosperity powers up reaper adoption

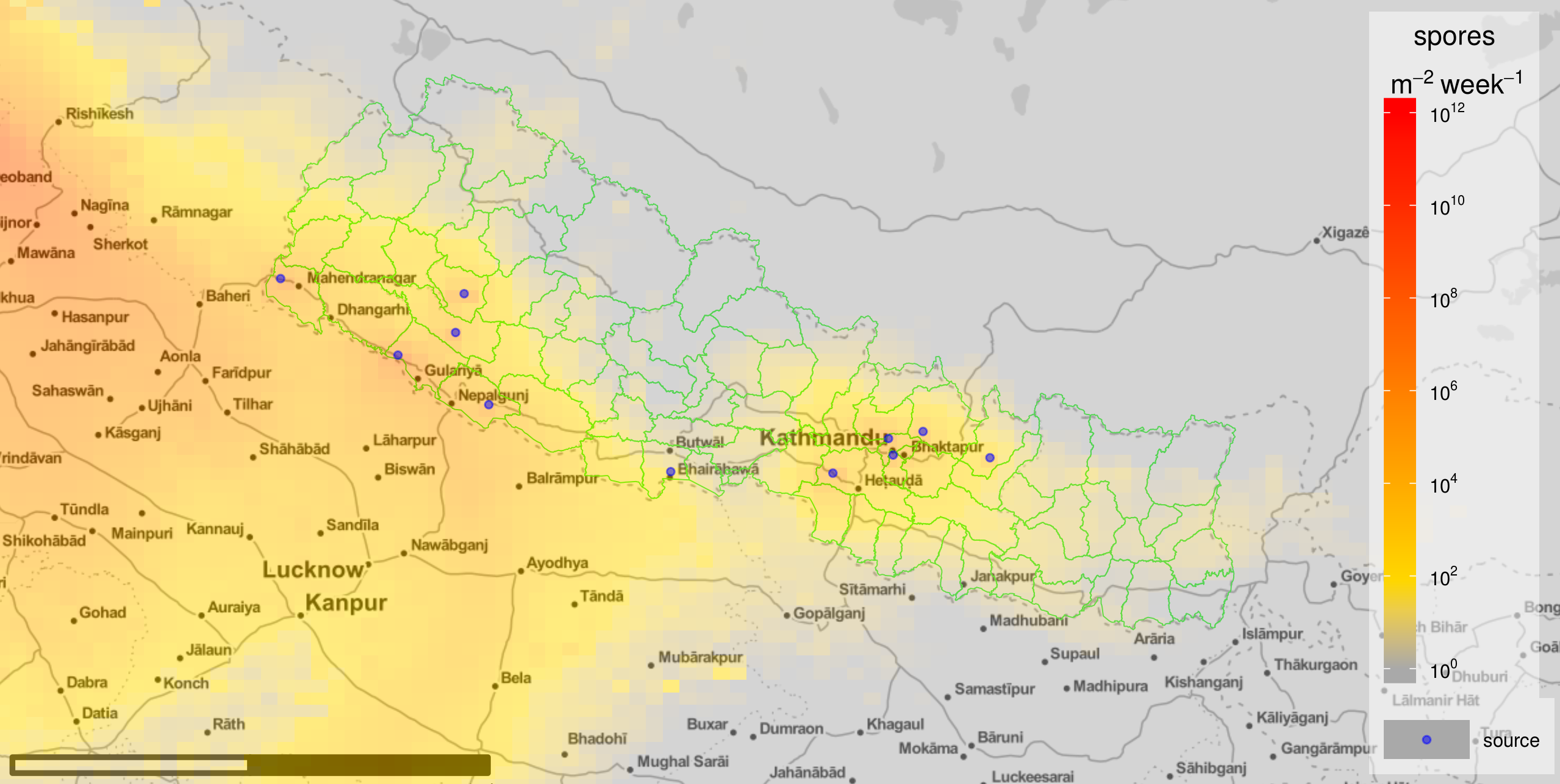

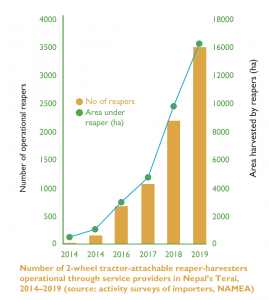

Over 4,000 mechanized reapers have been sold in Nepal with more than 50% in far and mid-west Nepal since researchers first introduced the technology five years ago. The successful adoption — which is now led by agricultural machinery dealers that were established or improved with CSISA’s support — has led nearly 24,000 farmers to have regular access to affordable crop harvesting services, said CIMMYT agricultural economist Gokul Paudel.

“Reapers improve farm management, adding a new layer of precision farming and reducing grain loss. Compared to manual harvesting mechanized reapers improve farming productivity that has shown to significantly increase average farm profitability when used for harvesting both rice and wheat,” he explained.

Nearly 65% of Nepal’s population works in agriculture, yet this South Asian country struggles to produce an adequate and affordable supply of food. The research indicated increased farm precision through the use of mechanized reapers boosts farm profitability by $120 a year when used for both rice and wheat harvests.

Oli agreed farmers see the benefit of his harvesting service as he has had no trouble finding customers. On an average year he serves 100 wheat and rice farmers in a 15 kilometer radius of his home.

“Investing in the reaper harvester worked for me. I earn 1,000 NRs [about $8] per hour harvesting fields and was able to pay off the purchase in one season. The added income ensures I can stay on top of bills and pay my children’s school fees.”

Farmers who have purchased reapers operate as service providers to other farms in their community, Paudel said.

“This has the additional benefit of creating legitimate jobs in rural areas, particularly needed among both migrant returnees who are seeking productive uses for earnings gained overseas that, at present, are mostly used for consumptive and unproductive sectors.”

“This additional work can also contribute to jobs for youth keeping them home rather than migrating,” he said.

The adoption rate of the reaper harvester is projected to reach 68% in the rice-wheat systems in the region within the next three years if current trends continue, significantly increasing access and affordability to the service.

Private and public support for mechanized harvester key to strong adoption

Achieving buy-in from the private and public sector was essential to the successful introduction and uptake of reaper attachments in Nepal, said Scott Justice, an agricultural and rural mechanization expert with the CSISA project.

Off the back of the popularity of the two-wheel tractor for planting and tilling, 22 reaper attachments were introduced by the researchers in 2014. Partnering with government institutions, the researchers facilitated demonstrations led by the private sector in farmers’ fields successfully building farmer demand and market-led supply.

“The reapers were introduced at the right place, at the right time. While nearly all Terai farmers for years had used tractor-powered threshing services, the region was suffering from labor scarcity or labor spikes where it took 25 people all day to cut one hectare of grain by hand. Farmers were in search of an easier and faster way to cut their grain,” Justice explained.

“Engaging the private and public sector in demonstrating the functionality and benefits of the reaper across different districts sparked rapidly increasing demand among farmers and service providers,” he said.

Early sales of the reaper attachments have mostly been directly to farmers without the need for considerable government subsidy. Much of the success was due to the researchers’ approach engaging multiple private sector suppliers and the Nepal Agricultural Machinery Entrepreneurs’ Association (NAMEA) and networks of machinery importers, traders, and dealers to ensure stocks of reapers were available at local level. The resulting competition led to 30-40% reduction in price contributing to increasing sales.

“With the technical support of researchers through the CSISA project we were able to import reaper attachments and run demonstrations to promote the technology as a sure investment for farmers and rural entrepreneurs,” said Krishna Sharma from Nepal Agricultural Machinery Entrepreneurs’ Association (NAMEA).

From 2015, the private sector capitalized on farmers’ interest in mechanized harvesting by importing reapers and running their own demonstrations and several radio jingles and sales continued to increase into the thousands, said Justice.

Building entrepreneurial capacity along the value chain

Through the CSISA project private dealers and public extension agencies were supported in developing training courses on the use of the reaper and basic business skills to ensure long-term success for farmers and rural entrepreneurs.

Training was essential in encouraging the emergence of mechanized service provision models and the market-based supply and repair chains required to support them, said CIMMYT agricultural mechanization engineer Subash Adhikari.

“Basic operational and business training for farmers who purchased a reaper enabled them to become service providers and successfully increased the access to reaper services and the amount of farms under improved management,” he said.

As commonly occurs when machinery adoption spreads, the availability of spare parts and repairs for reapers lagged behind sales. Researchers facilitated reaper repair training for district sales agent mechanics, as well as providing small grants for spare parts to build the value chain, Adhikari added.

Apart from hire services, mechanization creates additional opportunities for new business with repair and maintenance of equipment, sales and dealership of related businesses including transport and agro-processing along the value chain.

The Cereal Systems Initiative for South Asia (CSISA) aims to sustainably increase the productivity of cereal based cropping systems to improve food security and farmers’ livelihoods in Nepal. CSISA works with public and private partners to support the widespread adoption of affordable and climate-resilient farming technologies and practices, such as improved varieties of maize, wheat, rice and pulses, and mechanization.

Cover photo: A farmer uses a two-wheel tractor-mounted reaper to harvest wheat in Nepal. (Photo: Timothy J. Krupnik/CIMMYT)

Poverty reduction, livelihoods and jobs

Poverty reduction, livelihoods and jobs